They’re not your granddad’s daisy-wheel printer or your mom’s dots matrix. In reality, they have no resemblance at all to modern photo or document printers, which print in the boring two-dimensional. Like their name implies, 3D printers are able to create three-dimensional objects made of a variety of materials. They’re becoming more mainstream, popping in stores like Staples, Best Buy, and Home Depot, and you can purchase a variety of 3D printers as well as their accessories on Amazon.com as well as through other online stores. Although they’re still mostly seen on the floor of shops or in design studios, at communities and schools, and with enthusiasts, 3D printers are now being used on workbenchs, in recreation rooms, kitchens and even within a house near you at least in your own.

What is 3D Printing?

The simplest definition of 3D printing refers to a manufacturing method that involves laying material down, layer-by-layer to create a 3D object. (This is termed an additive process since the object is constructed from scratch, in contrast to subtractive processes where materials are cut and drilled, milled or removed.) While 3D printers make use of different types of materials (such as metal or plastic) and methods (see “How does 3D Printing work?” below) They all have the capability of turning digital files that contain three-dimensional information–whether made using a computer-aided design (CAD) or computer-aided manufacture (CAM) software or even from an 3D scanner — into physical objects.

Are 3D Printing Printing?

It is true that 3D printing is classified as printing, but not in the way it’s been traditionally defined. The Webster’s definitions for “printing” focus on the creation of printed materials photos, publications, or publications as well as the production of printed matter through the process of making impressions (the use or application of pressure). The definitions are not compatible with 3D printing. From a technical viewpoint, 3D printing is an evolution of traditional printing where a layer of substance (usually with ink) can be applied. The majority of the time, it’s so thin there’s no visible the height (though when using solid ink printers, it’s slightly more thicker). 3D printing can substantially increase that height with the use of multiple layers. Therefore, it could be sensible to expand print definition to encompass the creation of 3D objects in this way.

What is the process of 3D Printing Work?

Like traditional printers 3D printers make use of a variety of different technologies. The most well-known model is the fused deposition (FDM) and is also known as fused-filament fabrication (FFF). A filament composed of acrylonitrile butadiene (ABS) and polylactic acid (PLA) or another thermoplastic–is melt and then deposited by an extrusion nozzle heated in layers. The very first 3D printers that came to market, developed in the late 1990s by Stratasys with assistance from IBM, employed FDM (a word trademarked and that was trademarked by Stratasys) and so do the majority of 3D printers designed for the consumer or hobbyists as well as schools.

Another method that is used to create 3D printing involves stereolithography. In it, a UV laser is shined into a vat of ultraviolet-sensitive photopolymer, tracing the object to be created on its surface. The polymer is solidified when the beam comes into contact with it, as the light “prints” on the surface of the item layer by layer according to the directions in the CAD or CAM file that it’s working with.

In a different variation of this, you can also use the digital light projection (DLP) 3D printing. This technique exposes a liquid polymer the light of a digital light processing projector. The polymer is then cured layer-by-layer until an object is constructed and the liquid polymer is then drained away.

Multi-jet modeling is a 3D inkjet printing device that sprays a coloredglue-like binder on successive layers of the powder on which the object will be created. It is among the most efficient methods and also one of the few that can support multicolor printing.

It is possible to alter the standard inkjet printer to print with other materials than ink. DIY enthusiasts have constructed or modified print heads usually piezoelectric that can work with a variety of materials. Some even print the print heads using other 3D printers! Businesses like MicroFab Technologies sell 3D-capable print heads (as as well as complete print systems).

Selective laser Sintering (SLS) employs a high-powered laser to fuse the particles of metal, plastic, glass, or ceramic. After the process the remaining material is recycled. Electron beam melting (EBM) makes use of an electron beam in order to melt powdered metal layer-by-layer. Titanium is commonly used in EBM to make medical implants and aircraft parts.

Based on the method used the 3D printer can make use of various materials, including but not restricted to the use of metals (stainless steel solder, aluminum and titanium are among them) along with polymers and plastics (including composites that mix plastics with wood, metals and various other materials) as well as ceramics, plaster or glass; and foodstuffs such as cheese or icing and chocolate! ( See our primer on different filaments for 3D printers.)

Who was the first to invent 3D Printing?

First 3D printer, that utilized the stereolithography method was invented by Charles W. Hull in the mid-1980s. Stereolithography was traditionally an expensive technique for commercial use and machines can cost the range of five or six figures. However, recent times have seen the emergence of professional stereolithography printers for desktops priced at a few thousand and consumer models that cost less than a million dollars.

in 1986 Hull created 3D Systems the company which today offers 3D printers that employ different technologies. They offer everything from basic kits to sophisticated commercial systems in addition, 3D Systems also provides on-demand parts, usually for businesses.

What are the advantages of 3D printing?

With 3D printing designers are able to quickly transform concepts into 3D prototypes or models (a.k.a. “rapid prototyping”) and then make rapid changes to designs. It allows manufacturers to create items on demand instead of producing large quantities, thereby improving the management of inventory and decreasing storage space. People living in remote areas can make objects that otherwise would be unobtainable to them.

From a practical point of view, 3D printing can save both money and materials compared to subtractive processes, since minimal raw materials are wasted. The technology promises to transform the way manufacturing is done and eventually allow consumers to download 3D printing files to print complex 3D objects, like for instance, electronic devices in their home.

What can 3D printers make?

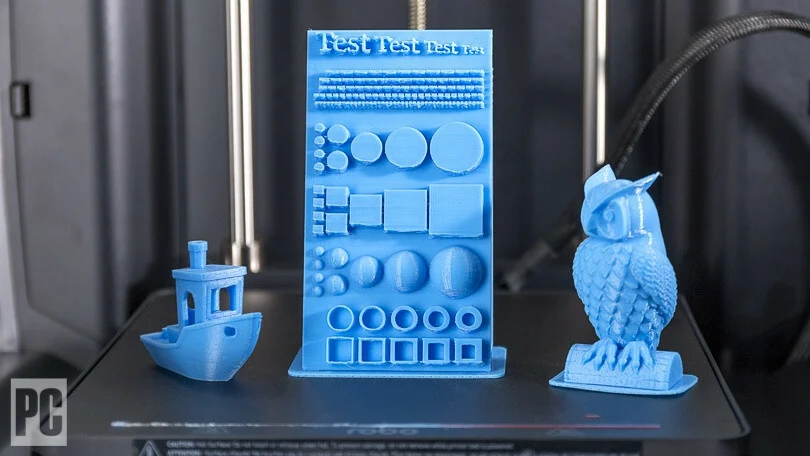

Designers make use of 3D printers to print out rapid prototypes and models of products and prototypes, but they’re now employed to design products that are finished, too. The products made using 3D printers are furniture, shoe designs and wax castings to make jewelry and tripods, tools, gifts as well as novelty objects, as well as toys. The aviation and automotive industries employ 3D printers to print parts. Artists can design sculptures and architects can create models of their plans. Archaeologists use 3D printers to recreate models of fragile artifacts which includes some antiquities that were damaged by ISIS. In the same way, paleontologists and their students are able to replicate dinosaur skeletons as well as other fossils. Take a look at the gallery below of practical and easy 3D printers and objects.

Doctors and medical professionals can make use of 3D printing to print the prosthetics and hearing aids artificial teeth, as well as bone grafts as well as replicating models of tumors, organs and other internal body structures based on CT scans prior to surgical procedures. An excellent illustration can be found in Project Daniel, which 3D-prints prosthetic hands and arms for victims of conflict in Sudan. There are 3D printers are being developed to put down layers of cells in order to create synthetic organs (such as kidneys(Opens in an entirely fresh opening) and blood vessels(Opens in an entirely New windows)) are already in the R&D stage. There’s even a role where you can use 3D printing for forensics, such as to recreate a bullet that was that was lodged in the body of a victim.

Printing electronics is a collection of printing methods that permit electronic circuitry or devices printing on a flexible material like labels, fabrics, or cardboard by applying optical or electronic inks. It allows for low-cost manufacturing of devices with low performance. The printed electronics industry is now beginning to be incorporated together with 3D printing, which permits printing of circuits or devices. One of the benefits of this highly effective combination is that in the future, you could be able print gadgets using 3D plans instead of buying them.

Food preparation is yet another way 3D printers can be utilized. For example, the French Culinary Institute has been employing a Fab@Home 3D open-source printer that was developed by Cornell University to prepare artistic food items as well as MIT has designed an edible 3D printer known as the Cornucopia. A few restaurants are testing prototypes for food printers. NASA’s 3D printing research has also included food printing, for example 3D-printed pizza.

A small number of food 3D printers are now commercially accessible. They typically focus on certain foods, such as pancakes, chocolate or cookies.

What is 3D Printing Services?

There is no requirement to own an expensive 3D printer in order to enjoy the benefits of one. There are many 3D printing providers, including Shapeways(Opens in brand new tab) and Sculpteo(Opens in an entirely brand new tab), print gifts and other items of a smaller size on orders using the company’s own 3D printers and then deliver them to customers. Customers can submit their own 3D object files or select items, mostly made by other customers of the service, by browsing an online store.

However, 3D Printing Service are not just the realm of experts. Big companies such as UPS(Opens in an entirely brand new tab) have introduced 3D printing options, and a few conventional print stores have also added the option of on-demand 3D printing into their offerings.

Where can I find an 3D Printer?

A majority of 3D printer manufacturers sell their products on the internet directly. Many online retailers now carry the printers, which includes online-only firms like Amazon.com and others that have brick and mortar stores. Certain of them include Walmart, Best Buy, and Staples have them available in their stores and online, but you should be certain to check the availability of their stores on their websites as not all retailers offer these devices. There are a number of 3D printers have been opened in large cities. For example, iMakr(Opens in a new window) has storefronts in London and New York City.

Some online stores are specialized on 3D printers, including Dynamism(Opens in an additional screen), which sells various 3D printers of various brands, and provides assistance to customers.

What software do I need to do 3D Printing?

The majority of 3D printers will accept files in the STL file format (named as stereolithography). These kinds of files can be created using any CAD program that ranges from costly commercial software such as AutoCAD to open-source or free software like Google SketchUp and Blender. If you don’t want to create your personal 3D documents, 3D object databases such as MakerBot’s Thingiverse(Opens in a new tab) offer numerous 3D objects which can be downloaded and printed.

The majority of 3D printers have software, either downloaded on disks or accessible for download which includes everything you need to print. The suites usually include an application to control the printer, as well as an encapsulator, which prepares for printing, converts the file into layers based upon the resolution you choose as well as other aspects. Some suites also include programs that can “heal” the file by fixing issues that might hinder smooth printing. The software was developed by the RepRap(Opens in an entirely fresh screen) open-source movement, that is where hobbyist 3D printing came into. With certain printers, you are able to select the component software programs you want to download, rather than working to the ones included within the suite.

What is the future in store in 3D Printing?

A range of 3D printers that are suitable for home and small-scale businesses is easily accessible– ch-tech.ch’s reviewed a variety of them–but they’re often thought of as expensive and costly gadgets. We expect that to change in the next couple of years, as 3D printers are expected to be more widespread in homes, and will be seen on workbenchs and in studios, the home office as well as in kitchens. They may not be found in every house however they’ll be essential for those who possess the devices. Most of the time the products created with 3D printers have been homogenous interiors, but we’ll soon begin to see more elaborate designs using composites and multiple materials along with printable electronic components. Today, with the advent of 3D printers in case you lose the cover for your TV remote’s battery It could be possible to print a new cover. In the future, if you’re unable to locate your remote, maybe you’ll be able print a brand new remote.

Additionally, 3D printing is gaining an edge in space. NASA is testing 3D printers aboard the International Space Station. The printers will eventually be used to build habitats on Mars and other planets. To prevent from the Apollo 13 astronauts from dying of carbon monoxide asphyxiation NASA was required to discover a way to squeeze an elongated peg inside an oval hole. If there was a 3D printer in the spacecraft the ship, they might have been able solve the issue by creating and printing the connector.

Astronauts aren’t able to swing through Home Depot if they need to replace a valve, or widget or other device, but 3D printers could make one in the event of need. We’ll also see 3D printers on Antarctic bases as well as other remote Earthly areas, where people don’t have time to wait for the next supply to replace their essential components or tools.

Applications for medical devices using 3D printing aren’t limited to hearing aids, prosthetics or dental crowns. (See “What can 3D Printers Produce?” above for a glimpse of what’s coming up.) The replacement parts don’t have to be limited to mechanical.

In the last few years, we’ve seen a surge in the range and applications of 3-D printing. It’s similar to the state of personal computers were in the year 1980. Although it’s not difficult to identify certain areas that the area of 3D printing is likely to develop into, some aren’t even possible to forecast, just as nobody in the year 1980 could have anticipated all about what the PC could become. The possibility is that 3D printing might not be as influential or impactful as computers on a daily, consumer level but it does have the potential to transform manufacturing and, perhaps even more crucially put it in the hands of consumers in everyday life. There’s one thing for certain however: 3D printing will be around for a while.